The pursuit of innovation frequently collides with the necessity of cost concerns in the fast-paced world of electronics manufacturing. Flexible printed circuits, or Flex PCBs, have become a cutting-edge option for many applications, but many have been left asking why they are so pricey. This article seeks to clarify the nuances around the cost elements of producing flexible printed circuit boards.

Complexity of Materials and Design

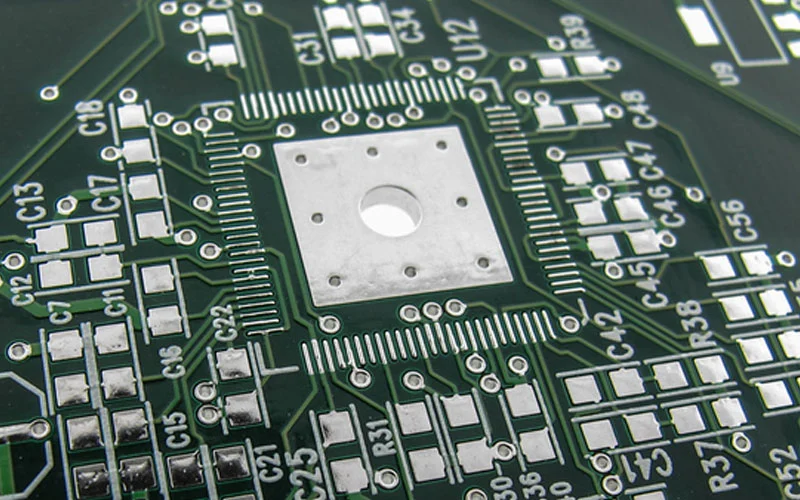

The main component of Flex PCBs is a flexible substrate, which is frequently composed of polyester or polyimide. These substances are picked because they can flex without compromising their structural integrity. However, producing flex pcb assembly substrates necessitates specific procedures like coating and lamination, which drive up the cost of materials.

Intricate Circuitry:

Complex circuit designs on Flex PCBs are frequently needed for sophisticated manufacturing processes like laser cutting and fine-line printing. These designs are sophisticated and need a higher level of ability, technology, and precision, which raises the cost of materials and labor.

Particularized Methods of Production

To make conductive traces, copper is added to the flexible substrate selectively during the additive manufacturing process used to create Flex PCBs. The more complex these processes—such as photolithography or screen printing—are compared to the subtractive techniques required to create stiff PCBs, which drives production costs.

Difficulties with Component Assembly

There are particular difficulties when assembling parts on flexible substrates. Precision and specific skills are required for soldering and attaching components to a flexible surface; these techniques sometimes involve robotics or automated assembly lines. These sophisticated assembling techniques make The manufacturing cycle more complex and expensive.

Quality Control and Testing

Flex PCBs are used in vital areas like aerospace and medical equipment. Thus, they need to be thoroughly tested to guarantee their dependability. Strict testing procedures, such as temperature cycling, impedance testing, and flex testing, are necessary to ensure the functionality and longevity of these circuits and greatly increase their total cost.

Standards for Quality Assurance:

It takes more time and money to meet strict quality assurance requirements, particularly in applications where electrical component failure is not an option. Certifications, industry standards observance, and compliance testing drive up the total cost of Flex PCBs.

Low Volumes of Production

Pcbasic Flex PCBs are frequently less in demand than rigid PCBs, which gain from economies of scale brought about by high production volumes. Because flexible circuitry is specialized, smaller production runs result in higher manufacturing costs per unit. Flex PCBs are still a niche product, but higher demand may result in lower prices.

Investments in Research and Development:

The constant hunt for new developments in flexible electronics motivates funding for R&D. Making significant financial investments is necessary to create new materials, improve manufacturing techniques, and expand design possibilities. These continuous R&D expenditures partly cause the increased upfront expenses related to Flex PCBs.

Read More: GPS Tracking Solutions

Conclusion:

Various variables, including complex design and material selection, specific manufacturing techniques, and stringent testing protocols, contribute to the greater cost of Flex PCBs. Improved production efficiency and economies of scale present opportunities for cost savings as the market for flexible electronics expands and technology advances. For now, though, the premium paid for Flex PCBs represents the outlay of funds necessary to capitalize on the advantages of flexibility, robustness, and adaptability in the constantly changing field of electronics production.